Wheels: Remove and Install Front VR4 Wheel Hubs

Contents

- 1 How to Remove and Reinstall Your Front Wheel Hubs

- 2 Required Tools

- 3 Other Helpful Tools

- 4 STEP 1: Remove the Wheel!

- 5 STEP 2: Remove the Brake Caliper

- 6 STEP 3: That Huge Nut

- 7 STEP 4: That Steering Arm Bolt

- 8 STEP 5: Messing Up Your Alignment! (We fix it later)

- 9 STEP 6: More Banging

- 10 STEP 7: Installing the New Hub!

How to Remove and Reinstall Your Front Wheel Hubs[edit]

Written by Matt "JustMatt" Pierson

Due to my front passenger wheel bearing going bad I decided to take the opportunity to do this write-up on the process. It's actually extremely easy when you know what to expect and no special tools are required. This is really written as an "idiots guide" so forgive me for explaining some of the more simple procedures.

So here's our patient:

My maroon '94 VR4 that looks pink for some reason when I take it to the car wash.

My maroon '94 VR4 that looks pink for some reason when I take it to the car wash.

While you do this, make sure you have jack stands set up in a place that allows the wheel hub to swing free from the suspension. If you're unsure what I mean by that, just keep reading and you'll see all the parts that need to move independently.

I was able to do one side in roughly 50 minutes and that was with taking pictures of the whole process and by no means hurrying.

Required Tools[edit]

- A hammer or a small mallet

- A ratchet

- 19mm socket

- 17mm socket

- 14mm socket

- 12mm wrench

- 17mm wrench

- Something to pry things apart with

- Channel Locks

- 1 1/4 Standard socket? (I didn't have a metric socket big enough to fit the axle nut, but this standard one fit perfectly fine. I torqued the living crap out of it and it never rounded off)

Other Helpful Tools[edit]

- Breaker bar

- Impact Gun (I'd highly suggest this as it'll likely cut your work time in half)

STEP 1: Remove the Wheel![edit]

If you can't do this on your own, you may want to consider selling your car.

STEP 2: Remove the Brake Caliper[edit]

There's two bolts on the back of the caliper. Take them off but don't let the caliper dangle on the brake line. I tied mine up to the springs with a zip tie to keep it out of the way.

A view from behind

After that, just yank the rotor off. If it's on there tight, you may want to use a rubber mallet to give it a couple love taps. Don't go crazy and start bashing it with a hammer, though.

STEP 3: That Huge Nut[edit]

This is your axle nut. It pretty much holds your wheel on. Don't take it lightly or it may kill you when you least expect it (I'm only partially joking, more on that later).

This is a great picture, because absolutely nothing is in focus.

First you need to pull the pin out. Clip off the ends with clippers if you want, we don't want to re-use the old one. The reason being that once you've bent it back and forth you've increased the risk of the ends snapping off, the pin sliding out, the nut shaking itself loose, and your wheel falling off.

In all honesty, I've replaced the old pin before and driven on it fine, but there comes a time when you're driving down the road... and you start thinking of that pin... and you imagine your wheel flying off at 65 miles per hour... and it haunts you all the way to your destination.

Moral of the story: Just replace the pin. It costs like 1 cent for a bajillion of them.

Now just get that nut off. Like I said before, 1 1/4 standard socket fits fine so use that if you don't have a metric socket that fits. It should be pretty tight so you may need a breaker bar. The problem is you're going to spin the wheel doing this, so you can either use an impact gun, or have someone hold the wheel from the other side with their God-like strength. I just use an impact.

If you need to have someone hold the wheel, make sure their fingers dont get smashed between the caliper and the wheel while you're turning the other side (it hurts so bad). Listen for screaming while you're turning it.

Once you get it off, this may or may not happen:

The end of my wheel hub just kinda fell out which, my first time, seemed like a fairly reasonable thing to happen. Once I got my new ones, however, I found that it was impossible to pull it apart like that, leading me to believe that this was a bad thing to happen.

Also, there's a small bolt on the back of the dust guard that holds the speed sensor line in place. Just take the bolt out.

My knee is in focus, at least. The bolt you're looking for is the one almost dead center of the picture that you can't really see because I'm a horrible photographer.

STEP 4: That Steering Arm Bolt[edit]

The bolt itself is easy. Yank that pin out (for God's sake, replace the pin) and take the bolt off. Sometimes when I put the pin back on the stud will just spin around with the nut, but this has never happened to me while taking the nut off. If it does happen to you, use the channel locks to press the two pieces together in order to hold the stud in place. May require a third arm or at least a friend.

Now don't bang on the top of the stud to make it slide out. You actually want to bang on the side of the top half of the knucle to make the stud slide down.

I know it seems weird, but banging on the side WILL make it pop out. We're working with vibrations here. If you're concerned about the dents mine has in it, I suppose you could try placing a block of wood there or something, but really, you're not going to damage anything unless you're using a jack hammer (and even then I'd be surprised). Don't bang anywhere else but where I've pointed, you'll likely break something if you do. I generally have to smack the thing quite hard, so don't be surprised if you really have to whack it.

STEP 5: Messing Up Your Alignment! (We fix it later)[edit]

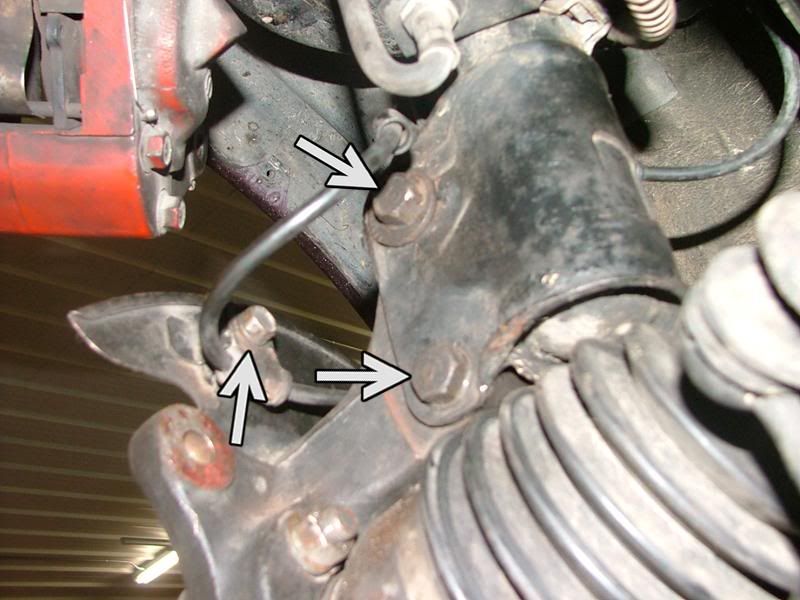

Here's the next two bolts we're going to take out (the one to the left should already be out, I marked that one for some reason, but ignore it):

The top one actually controls your wheel's camber, the bottom one is just a chump bolt that holds things together.

What we want to do is put a mark on the bolt so you can put things back together correctly. I just scratched my marks into the metal but paint might be a better idea if you have some lying around:

Now, I'm no camber specialist, but I can tell you that this is a pretty simple mechanism here. The bolt is offset from the center on that built-on washer thing, so when you rotate the bolt, the washer pushes against that little lip there to move the wheel on its axis. I know, I'm doing a horrible job of explaining it, so just play around with it and you'll understand.

To get them off, just do it like any other nut, you may have to use your regular 17mm wrench on one side with the 17mm socket on the other side, especially for the bottom one. This may not be necessary for the top one, since it tends to keep itself snug:

To get the bolts out, you'll first want to spin the camber nut around so the washer isn't pressing against anything. That way you can wiggle the strut back and forth while you yank on the bolt. I usually take the bottom one out first. The top one may require some love taps and wiggling at the same time. Just remember which way the top one goes in, since the camber adjustment will only work on one side of the strut. Just wiggle like a lunatic and it'll come out eventually.

Once both bolts are out you may be able to wiggle the hub free of the strut. If not, just get something long and metal to stick in there to pry it apart. Don't go crazy, though, because the sensor wire can get caught on the hub and you don't want to break that. Use some finesse.

So now you may be met with this abomination:

Once again, my hub is just falling to pieces. Pull the axle out of the hub and if that little metal ring comes with it, pull that off too and set it aside.

STEP 6: More Banging[edit]

If you pull the hub towards you and look at the back you'll see four nuts on the ends of four bolts. Take the nuts off (once again an impact really comes in handy here, mine were quite tough).

Now simply slide the hub out!

Not really. You'll have to either wait it out or take it by force.

ProTip: Don't wait it out.

Take one of your nuts (this may ruin your nut) and half-thread it onto one of the studs. Take your hammer or mallet and hit the top of the nut. You can start with some taps but stop kidding yourself and give it a healthy bashing. If you know you're replacing the hub, by all means just bash away on the top of the stud but this method is for preserving your hub on the off chance that it's not completely trashed.

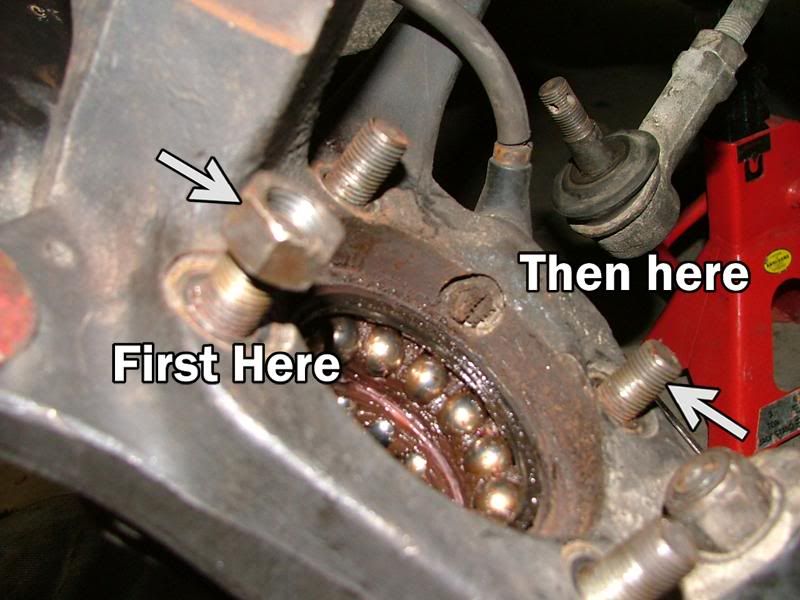

Move back and forth between one stud and the one at the complete opposite corner. Just hit them till one part comes out a little bit then switch to the other one.

Making some progress.

Making some progress.

Once its finally out, I hope you don't have to see what I saw:

But the new one looks great!

Guess which one's the new one.

STEP 7: Installing the New Hub![edit]

Obviously, installing the new one is pretty much doing all that stuff in reverse, so I'll go over it quickly and provide some things for you to watch out for. I will recommend you skip to the part about making the holes line up for the camber bolt, though.

First and foremost is that my new hub was a bit different. Rather than having studs that require nuts to go in from the back, the new one has bolts that go in from the back and thread into the hub itself. I don't know if this was something put onto the later model 3Ks but it's no big deal. Just line the holes up and thread the new bolts in from the back.

Also note that the holes wont line up if you have the hub sideways. If they dont line up at all, DO NOT PANIC. Just twist it 90 degrees in either direction and they'll line up.

I don't have torque specs for any of these, but for these (and pretty much all the other ones) I just torqued them down good and tight. This stuff holds your wheel on! Also, don't forget the lock washers.

Making the camber bolt holes line up.

The part that slides into the strut was rusted nicely on my car, so it was almost impossible to do by hand. I used a floor jack to jack the bottom of the hub up (dont bend your dust shield) till the holes lined up, but don't jack it up so high that you're lifting the car off the jacks. Just use common sense. If you have to use any real force at all on the floor jack, you're probably doing something wrong. Just use one hand to work the jack and the other to guide the hub.

Once the holes are pretty close, shove the bottom bolt in first. Once again, you'll probably have to wiggle the strut around and mess with the jack a bit (A guide pin comes in handy here). Once its in, just thread the bolt on with your fingers, but not all the way. You'll want to do plenty of wiggling to get the camber bolt in. Make sure it's facing the right direction!

I had to give the camber bolt a couple taps with the mallet while wiggling to get it completely in (and make sure the seven notches on the washer part are facing straight down, otherwise it probably wont go on all the way). Then tighten the crap out of the nuts (dont forget lock washers). Once again, you may need to hold a wrench on one side in order to get them completely tight.

AND DONT FORGET TO LINE YOUR MARKS UP SO YOU DONT SCREW UP YOUR ALIGNMENT.

This is what it looks like when you've screwed up your alignment. Just twist the top bolt so the marks you put in earlier line up.

Put the little bolt back into the dust cover. Remember the little guy that holds the sensor in place?

The steering arm knuckle is fairly simple. Just put that bolt on AND PUT A NEW PIN IN. Bend the ends of the pin so that it can't walk itself out. As I said before, if the bolt and the nut end up spinning together, get a large pair of channel locks and crush the two parts together and that'll hold the bolt in place and let you torque the nut down.

Same thing for the axle bolt. I torque the crap out of mine. The reason I needed to replace my hubs in the first place was because my axle nuts were loose. I drove about five hundred miles on a wiggly wheel hub and took it to the drag strip a couple times. Needless to say, my hubs were pretty well destroyed after that.

Don't forget the huge lock washer behind the nut, either.

Put your rotor and brake caliper back on. Rotor slides over your new hub and caliper slides over that and lines up with the holes in back. I always have trouble getting the pads to fit around the rotor. Just use one hand to hold the pads apart and the other to guide the caliper over. Once it's on, slide a bolt through the caliper's hole and feel around till it drops into the threaded hole on the hub. Thread it partially in and line the other one up the same way. Torque them down.

Make sure the dust guard isn't touching the rotor. This is a stupid thing I overlook almost every time I do anything to my car. I take it out for a test drive and 3 seconds down the road I hear "SCREEEEEEEEEEEEEEEEEEEEEEEEEEEEEEECH" and wonder what I managed to mess up. It's always the dust cover. Just bend it away from the rotor, no need to be scientific about it.

You're good to go! Just slap your wheels back on and experience the feel of brand new wheel hubs.

If you have any questions or have noticed any errors in this article, feel free to e-mail me at HwFRemington@gmail.com