Engine: Replace Valve Stem Seals (VSS)

What are Valve Stem Seals (VSS)? . . . and why would be want to replace them?

The valve "stem" passes from the above the head, where there is a lot of oil, into the intake and exhaust tracts. When the seals get old, they become brittle and lose their ability to seal. Then oil can leak past the seals and get to the combustion chamber and exhaust, resulting in smoke out the tail pipe.

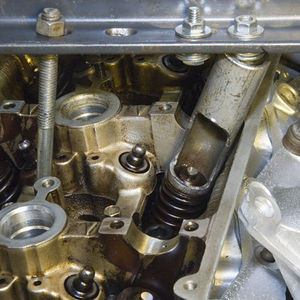

These pictures give basic idea of parts involved:

This top view is with the cams and lifters removed, it illustrates how little clearance there is around the outside of the valve springs. Some valve spring compressors will not work in these conditions. Notice in lower-left corner is a light blue rag stuffed into oil drain passageway in the head, this will be mentioned later. |

This article will give some ideas on the steps needed to replace the seals. Hopefully there is enough information to help you decide how you want to tackle the job. For now, there will be no discussion on how to remove all the necessary engine accessories etc to get to the seals. It will be assumed the engine is already opened up.

There are probably 4 different basic scenarios:

- Heads removed (easiest condition for seal replacement, but not practical unless removing heads for other reasons)

- Engine out of car, but heads attached, (next easiest for seals, but again only if engine is already removed)

- Engine in car, with timing belt and cams removed, (harder than 2 to remove seals because it is harder to reach things, and maneuver tool, but certainly easier than removing entire engine first)

- Engine in car, cams in place (has been done, but seems like it would be very difficult to get the springs out etc. . . . Even though the actual seal replacement would be harder, might be worth it, instead of removing timing belt, cams, etc.)

Tools[edit]

Depending on which method you use, the type of tool will be different. Here are some examples. We can add more tools to this section as we come across them.

| If heads are removed, then using a C-type valve spring compressor would probably be the easiest, because it would allow both hands to be used to remove (and later replace) the tiny keepers. | |

| With heads attached, one option is this special Mitsubishi tool, it would also allow two hands to remove and replace the keepers. The disadvantage is the high cost of the tool, unless you can find one to borrow. | |

| Another option of purchased tool is this specialized one. Description from SnapOn ad --> Quickly removes and installs valve keepers on most overhead cam engines with valve stems from 4.5 to 7.5mm. Push or tap tool with a hammer to remove valve keepers. A magnet in the tool body captures the keepers for quick removal and valve disassembly. To install keepers, load keepers then push or tap to install. Can be used on the vehicle or on workbench.

Note that this tool will require you to push down on it with enough force to compress the valve springs. This may be easy if you have a good angle on it, wearing gloves etc. . . there is also a option to "tap" it with a hammer, although that might require good technique. I think if this could be rigged to a lever somehow, it would make the job very easy. Thread describing how to use it: : Tool Tips - removing valve keepers One option for buying: : GA317, Remover/Installer, Metric Valve Keeper

|

|

| Some examples of homemade tools. One of them is very simple to build, and uses a piece of pipe to press against the valve retainer.

The next picture shows an example of an alternate to the piece of pipe. It is harder to construct, but would allow the springs to be compressed without removing cams from the engine. |

Background[edit]

After doing some research on the various methods and tools, I decided to take the route suggested by this thread posted to forum by OthercarisaFiat: : Valve Spring Compressor for $15

I suggest you read the first couple pages of this thread to get some background. Much of what is shown in this instruction might assume that you already know some of the info mentioned in the thread.

OthercarisaFiat used a homemade tool to change his seals IN the car. I used a similar tool to change my seals with the engine on a stand. The biggest difference of course, is that I had no clearance problems with firewall/radiator etc.

Starting on about post #90 of the thread some members (primarily Cbatters and skunkworks) have worked some kinks out of replacing the seals without removing the cams. This is a very interesting way to do it, but will not work with the homemade tool shown here. It will take a tool that can "reach around" the cams to depress the valve spring. Since I already had the timing belt etc. removed, it was easy to remove the cams, so a simplier (to make) tool was my choice. It only took about 20 minutes for me to make the tool I used.

In my case the tool was free, made from parts in my steel bin. It looks a little different from OthercarisaFiat, but the concept is the same. Biggest difference might be that I used holes spaced about 4" apart. I found that easier to maneuver the pipe section while removing and installing the keepers.

Procedure (cams removed, homemade tool)[edit]

Before starting, you may want to stuff something into the oil drains in the heads. You would not want to drop any of the keepers down into the depths of the engine.

|

|

| 4. Compress the spring. Note that the valve will probably move approx 1/8" until it hits the piston, and will stop there. You could pressurize the combustion chamber with air compressor and special sparkplug adapter. That would prevent the valve from moving down at all. . . I chose not to do that, because it is easy to remove the keepers even though the valve moved, and I thought it would take longer to fool with air compressor. Also if you pressurize the chamber, you run the risk of the piston moving to bottom, (if crank is not fixed from turning) which could allow the valve to drop into cylinder. We sure do not want that to happen! | |

| 5. Remove the keepers with a magnet, or other tool of choice. Note that it may be necessary to loosen the keepers first with a screwdriver, (some of mine were stuck to valve stem. | |

| 6. Lift out spring and retainer. The picture shows these parts sitting on seat, before removal. | |

| 7. Remove old seal with needle-nose pliers, or other suitable tool. Start by rotating the seal about 45 degrees to break it loose, then while rotating back-and-forth, pull the seal straight up. Use care not to hit the pliers on the valve stem. | |

| 8. Place new seal on valve stem by hand, slide down to head.

9. Push seal until fully seated by using a special tool or deep-well socket, (I used 13mm). I should have taken picture, but it should be obvious what you need to do. You can feel when it hits "home". 10. Pull valve up (the seal should hold it up), to make it easier to install keepers in a later step. |

11. Replace spring and retainer

12. Clean oil off inside of keepers, then apply some vaseline or grease. This will help them "stick" to the valve stem in a step 14.

13. Compress spring with tool. (Same picture as step 4.) If you use care not to push the valve down, then it will be easier to install the keepers in next steps. If the valve does get pushed down, however, it is easy to pull it back up with finger, or screwdriver.

14. Install first keeper, the "suction" of the vaseline/grease will hold it to valve stem, then rotate it to the back of the stem. Just kinda push it around with your finger.

15. Install the 2nd keeper. After a little practice this will become easy. Everyone will probably come up with a method that works best for them. One suggestion I saw was to use vaseline on side of flat screwdriver to hold the keeper while moving into place. I did this once when I could not reach my fingers in to the valve stem.

16. Release the spring.

17. Admire your work . . . you are 1/24th closer to being finished.

18. Repeat step 2 on each valve until that cylinder is finished, then repeat step 1 five more times.

Don't forget to remove anything that you stuffed into the drain holes.

800 9/08

Update 11/11 CntrlSwitch VSS How-To